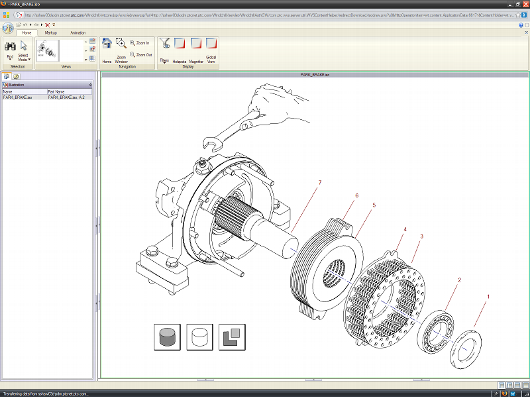

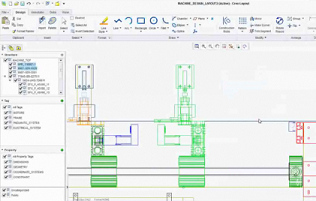

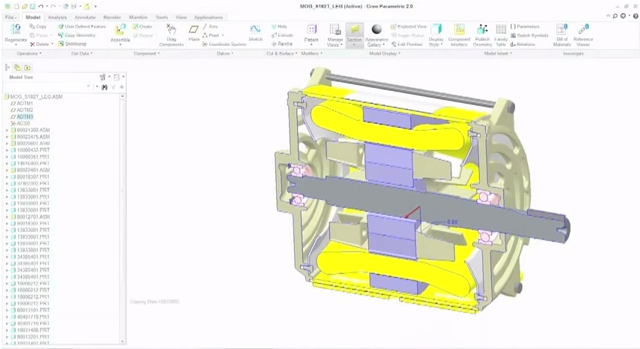

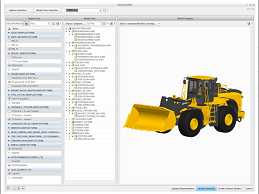

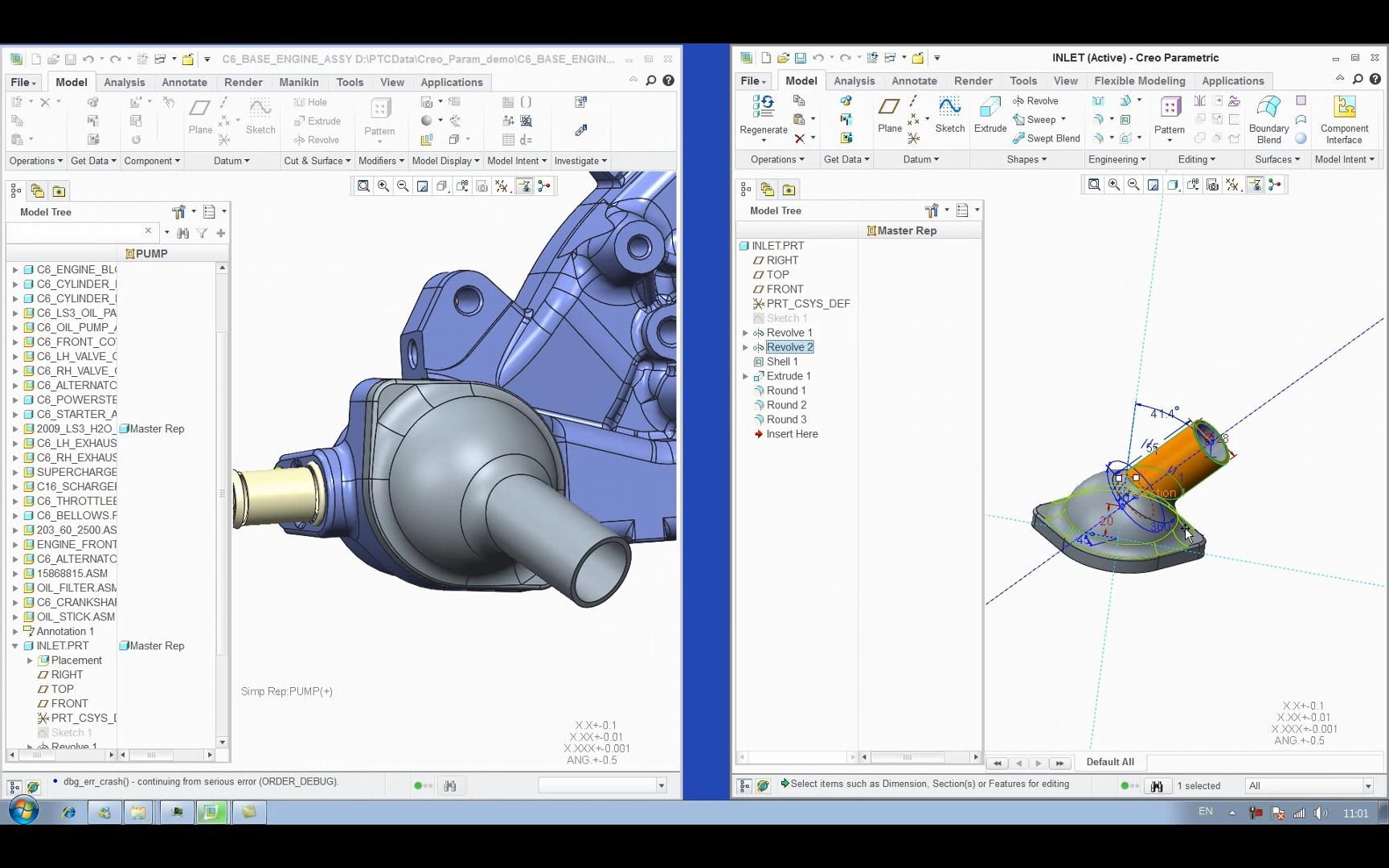

With a large assembly, there are a lot of interconnected parts, which makes it very complex to work with. Often, the model is so complex and it has so many parts that it’s hard for your CAD system to load it all up easily or quickly. This wastes time and means you can’t get on with your work. Also, with large assemblies, it is harder to ensure that all of the different parts work together. With more parts, there are more chances for things to go wrong.